资源简介

本资源提供自己创作的机器人焊接轨迹规划matlab仿真相关代码,包括直线焊接、圆弧点焊、空间移动等功能,提供10余个m文件,可供直接建立功能调用使用

代码片段和文件信息

function [ p ] = calcCircleMotGlobalParameter( pmArcWelding )

%UNtitleD2 Summary of this function goes here

% Detailed explanation goes here

quatFstPoint = angle2quat(mArcWelding.axisposPointS(4)mArcWelding.axisposPointS(5)mArcWelding.axisposPointS(6));

quatMidPoint = angle2quat(mArcWelding.axisposPointM(4)mArcWelding.axisposPointM(5)mArcWelding.axisposPointM(6));

quatEndPoint = angle2quat(mArcWelding.axisposPointE(4)mArcWelding.axisposPointE(5)mArcWelding.axisposPointE(6));

%% 这里好像有问题,当画整圆时候就变成不画了

if abs(abs(mArcWelding.lrArcRotatedDegreeSigned) - 2*pi) < 0.0001

tmpDot = 0;

angle1st = 0;

angle2nd = 0;

circleOrientAngle = 0;

else

%% 计算前两个姿态间夹角

tmpDot = quatFstPoint(1)*quatMidPoint(1) + quatFstPoint(2)*quatMidPoint(2) + quatFstPoint(3)*quatMidPoint(3) + quatFstPoint(4)*quatMidPoint(4);

if tmpDot > 1

angle1st = 0;

elseif tmpDot < -1

angle1st = 360;

else

angle1st = 2 * acos(tmpDot) * 180/pi;

end

if abs(angle1st) < 0.0001

angle1st = 0;

end

%% 计算后两个姿态间的夹角

tmpDot = quatEndPoint(1)*quatMidPoint(1) + quatEndPoint(2)*quatMidPoint(2) + quatEndPoint(3)*quatMidPoint(3) + quatEndPoint(4)*quatMidPoint(4);

if tmpDot >= 1

angle2nd = 0;

else if tmpDot <= -1

angle2nd = 360;

else

angle2nd = 2*acos(tmpDot) *180/pi;

end

end

if abs(angle2nd) < 0.0001

angle2nd = 0;

end

circleOrientAngle = angle1st + angle2nd;

%% 将姿态角度赋给P变量

p.arrCirclePhyPara(15) = circleOrientAngle;

%% 分发加减速规划算法

p = IssueAccDecTime(pmArcWelding);

end

end

%% 速度加速度分发算法

function [ p ] = IssueAccDecTime( pmArcWelding )

if ~mArcWelding.bWelding

p= AccDecNormalTime(pmArcWelding);

else

switch mArcWelding.nWeldingMode

case 0

p = AccDecArcWeldingModeTime0(pmArcWelding);

case 1

p = AccDecArcWeldingModeTime1(pmArcWelding);

case 2

p = AccDecArcWeldingModeTime2(pmArcWelding);

case 3

p = AccDecArcWeldingModeTime3(pmArcWelding);

case 4

p = AccDecArcWeldingModeTime4(pmArcWelding);

otherwise

p = AccDecArcWeldingModeTime0(pmArcWelding);

end

end

end

%% 正常状态下

function [ p ] = AccDecNormalTime( pmArcWelding )

%% 2.1先计算圆弧位置运动所需时间

circleVConstPos = p.lrVelIn;

circleAccPos = p.lrAccIn;

circleDecPos = p.lrDecIn;

posTimeSpan = calculateNormalMoveTime(p.arrCirclePhyPara(5)circleAccPoscircleVConstPoscircleDecPos);

%% 2.2再计算直线姿态运动所需时间

circleVConstOrient = p.lrVelOri;

circleAccOrient = p.lrAccOri;

circleDecOrient = p.lrDecOri;

orientTimeSpan = calculateNormalMoveTime(p.arrCirclePhyPara(15)circleAccOrientcircleVConstOrientcircleDecOrient);

%% 2.3统筹位置和姿态运动各段时间

if (sum(posTimeSpan) >= sum(orientTimeSpan))

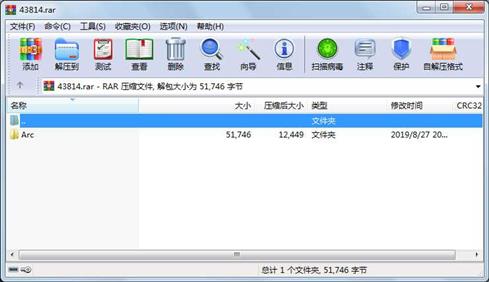

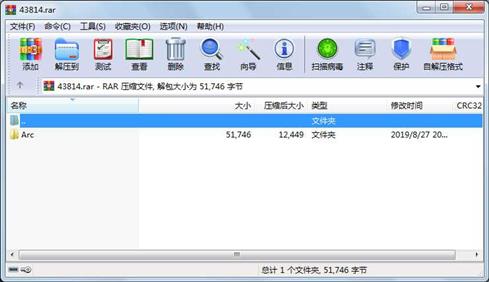

属性 大小 日期 时间 名称

----------- --------- ---------- ----- ----

文件 9687 2018-10-16 15:35 Arc\calcCircleMotGlobalParameter.m

文件 5683 2018-10-15 17:11 Arc\circleOrientInterp.m

文件 2269 2018-10-16 14:32 Arc\circlePosInterp.m

文件 13260 2018-10-16 08:30 Arc\GetSixAnglesIK.m

文件 11067 2018-10-23 15:52 Arc\InvArc.m

文件 2838 2018-10-16 14:33 Arc\IssueCalculateNextPos.m

文件 1217 2018-09-07 10:58 Arc\IssueVel.m

文件 436 2018-10-16 14:40 Arc\MoveArc.m

文件 4872 2018-10-22 16:54 Arc\m_CalcCirCenterRadius.m

文件 322 2018-10-22 17:43 Arc\test.m

文件 95 2018-10-22 17:38 Arc\try.m

目录 0 2019-08-27 20:03 Arc

----------- --------- ---------- ----- ----

51746 12

相关资源

- 3-PRS并联机器人工作空间分析

- 清洁机器人路径规划matlab仿真程序

- Matlab delta机器人的空间仿真程式

- rbf神经网络求解机器人的运动学逆解

- 基于遗传算法的机器人路径规划matl

- 单机器人的多任务路径规划GUI

- UR5机械臂MATLAB下轨迹规划

- 6自由度机器人正逆运动学matlab

- matlab 机器人避障程序

- matlab开发-基于遗传算法的机器人运动

- 机器人 matlab 程序

- matlab机器人工具箱使用手册.pdf

- Robotics Modelling Planning and Control

- 空间二连杆机器人的动力学建模及其

- 基于智能优化的机器人路径规划matl

-

机器人避障含simuli

nk仿真 - 自主移动机器人路径规划新方法含m

- 二自由度并联机器人的动力学建模与

- 六自由度涂胶机器人运动学仿真

- 机器人学导论课后习题MATLAB

- 多机器人路径规划-matlab

- 机器人学导论 课后习题参考

- 多机器人路径及避障规划——Matlab

- 基于蒙特卡洛法的模块化机器人工作

- 基于matlab的机器人最优路径规划仿真

- 六轴机器人逆运动的MATLAB程序

- 多种蚁群算法在机器人路径规划中的

- 机器人工具箱10.1

- 机器人控制系统的设计与MATLAB仿真刘

- 基于A-Star算法的机器人路径规划.rar

川公网安备 51152502000135号

川公网安备 51152502000135号

评论

共有 条评论